Please be aware all our patterns

Find out how you can build a raised garden bed out of Adbri Masonry's new DIY Concrete Sleeper. This video will take you through the steps to DIY a raised ga.

Concrete Molds From Wood Concrete Mold Concrete diy, Concrete sleepers, Backyard landscapes

This video is brought to you in partnership with The Home Channel, DStv channel 176. For more great home and gardening shows, tune in or visit https://www.th.

Services « Complete prestressed concrete sleeper production from design to plant installation

TSF-A supports the worldwide railway expansion with high quality, prestressed switch concrete sleepers that are preassembled as required and delivered to construction sites just-in-time. As a joint-venture between Kirchdorfer Group - Austria's leading precast concrete manufacturer - and the voestalpine VAE Group - the global market.

Manufacturing Concrete Sleepers Durawall

Diy Concrete Sleeper Moulds / Molds, Brisbane, Queensland, Australia. 1,811 likes · 2 talking about this · 1 was here. Concrete sleeper Molds Patterned.

Concrete Sleeper Moulds (Beton Travers kalıpları)

The expertise and technical knowledge that Weckenmann has created and developed for the precast concrete industry since 1965 also allows the setting up of modern and successful production plants for track and turnout sleepers made of prestressed concrete. We supply both stationary production lines and circulation systems as part of our product.

Concrete Sleeper Cope Industries

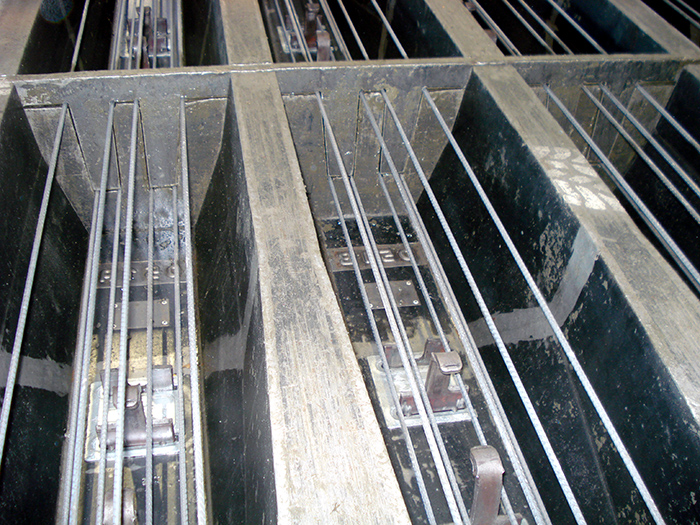

The mold is then turned back by 180° and returned to the mold circulation. The prestressed concrete sleepers are delivered ready for laying. For this purpose, the entire reinforcement is installed in the sleepers and prestressed in accordance with the relevant standards. The rail fastenings are completely assembled as well.

Beaudesert QLD Diy Concrete Sleeper Moulds/Molds.

The average timber sleeper weighs around 160lb-250lb, whereas an equivalent sleeper made of concrete could weigh anything up to 800lb. This means that wooden sleepers are quicker and easier to install initially and require little to no specialist equipment or vehicles for maintenance, which means cost-savings for rail operators.

Concrete sleeper mold GK Railway

RMS is a leading global provider of pre-stressed concrete sleeper technology. This is our entire focus.. RMS have successfully supplied our company with a long line production system and moulds to cast B70 type sleepers. The moulds produce accurate to guage sleepers, and equipment supplied is to a high quality and accuracy. Miran Klemar.

Equipment for concrete sleeper plants and sleeper moulds semie.cz

The cost of concrete sleepers vs. other types of retaining walls, such as wood or earth, is often higher due to the additional labor required to create and place the concrete blocks in the trench. Concrete sleepers retaining wall can cost from $350 per square metres up to 1 metre high and $900 per square metre up to 3 Metres high. 2.

Manufacturing Concrete Sleepers Durawall

Our concrete sleeper moulds are adressed to all those customers who: intend to setup a new precasting plant, intend to produce different types of sleepers, need more moulds in their existing carousel or long-line system plants. Concrete Sleeper Mould Railway Seat Plate Deployment of The Moulds Production of Sleeper Mould

We hand craft latex and

Welcome to RMS « Complete pre-stressed concrete sleeper production from design to plant installation « Railways Moulds and Systems (RMS) Location: RMS The bedrock of railway infrastructure worldwide Without dependable sleepers to support the rails of all types of track, from narrow gauge to heavy freight, there would be no railway system.

to RMS « Complete prestressed concrete sleeper production from design to plant

Concrete Sleeper Moulds Sleeper Forms for Pre-stressed Concrete Railway Sleepers. Machining and Welding Many years of experiences in machining, Mipsan has the capacity to perfectly meet the tolerances and standards asked by our customers. © 2012 Mipsan Makina / Merve Mah. Necip Fazıl Cd.

Diy concrete sleeper moulds/molds

The recipe for the cement mix is 6 parts fine gravel, 4 parts sand and 2½ parts cement. After deciding on the basic design and dimensions of the cement sleeper, you need to make a metal mould. You can make a mould from 3mm galvanised steel plate.

Production of Moulds for B70 Type Concrete Sleepers YouTube

Durawall has been manufacturing concrete sleepers for over 10 years. Engineer designed to last 60 years. Unique designs and colours available

Sleepers Concrete Melbourne Col Smith colsmithdelivers

Abstract. The aim of this research was to investigate the feasibility of a hybrid FRP-concrete beam as a rail sleeper. It was hoped that the new design would overcome some of the sustainability.

Manufacturing Concrete Sleepers Durawall

$ 189.99 Availability: Out of Stock Add to Wishlist Compare Log / Railway Sleeper Mould Approximate Size: 1200mm x 190mm x 70mm. This latex mould is ideal for anyone wishing to make their own log railway sleepers. It has a wood-effect pattern and. $ 159.99 Availability: Out of Stock Add to Wishlist Compare